Back to top

Shree Krishna Technomac is a trusted manufacturer and supplier of precision-engineered Pilger Die and Mandrels. Headquartered in Chhatral, Gujarat, India, we have been serving the metal forming and tube manufacturing industries since 2017. With a strong commitment to engineering excellence, we strive to deliver products with productivity and Quality assurance that match global standards in both performance and durability.

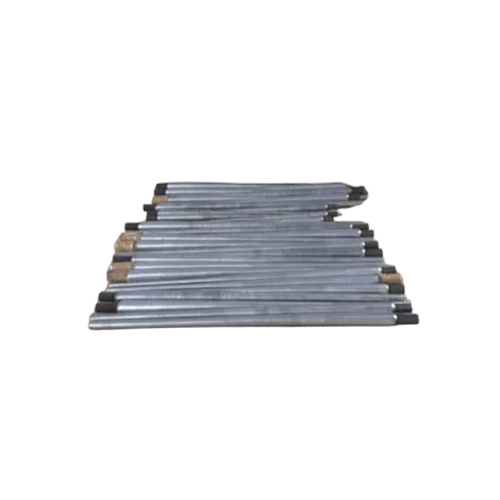

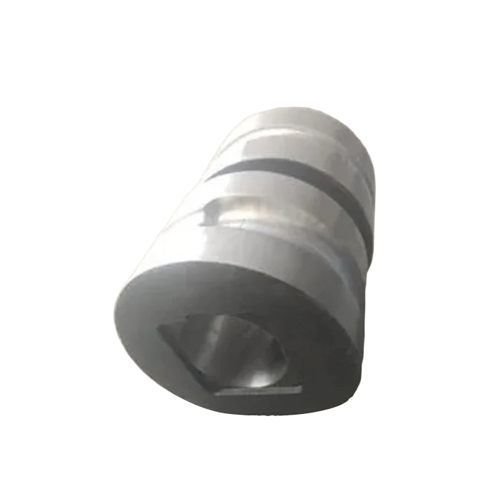

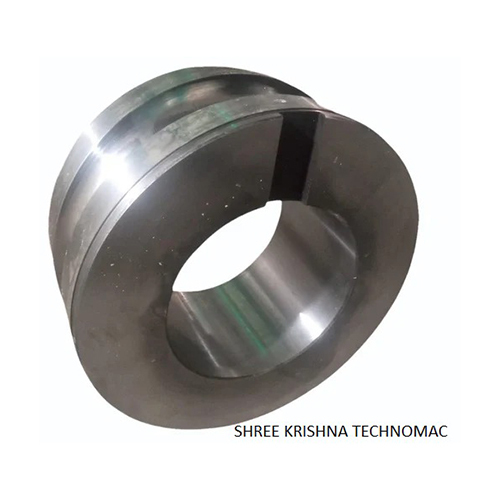

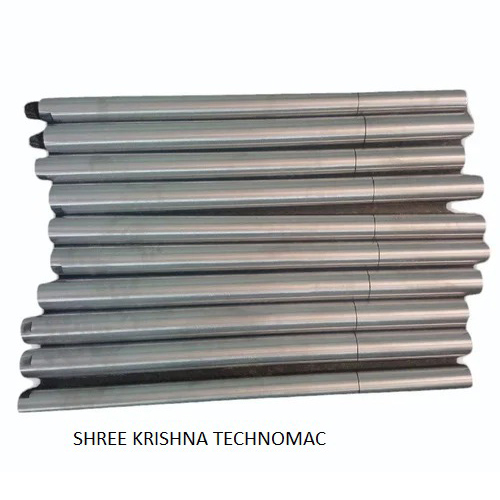

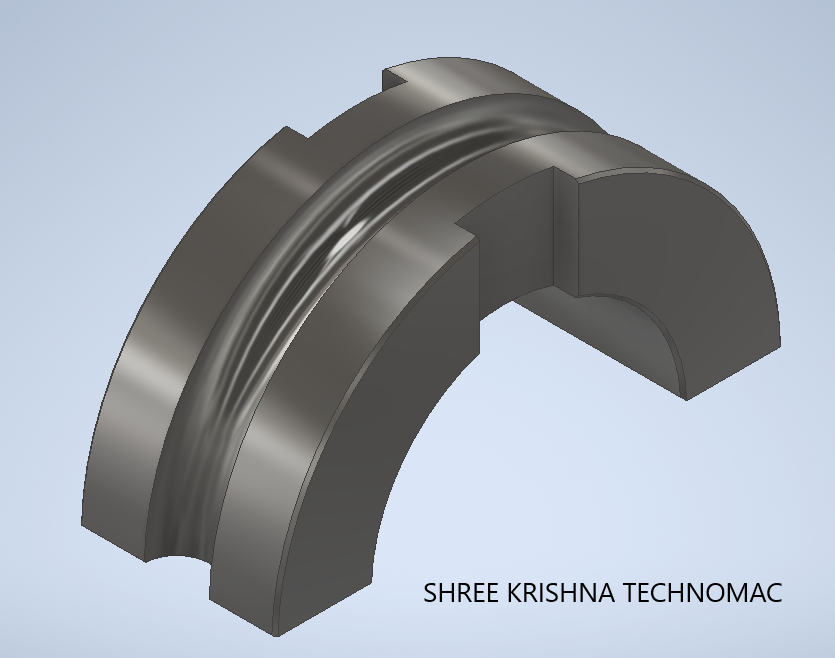

We manufacture a wide range of specialized pilger tooling including all types of Pilger Die & Mandrel. These components are essential in cold pilgering operations, and our products are crafted with precision to ensure reliable results and high operational efficiency in critical forming applications.

Indian, China & Russian Make with a different types of Pilger model Die and Mandrel, with Full and Half Ring Pilger Die engineered for precision, built for durability, and trusted for consistent performance in tubes rolling application.

Shree Krishna Technomac is a trusted manufacturer and supplier of precision-engineered Pilger Die and Mandrels. Headquartered in Chhatral, Gujarat, India, we have been serving the metal forming and tube manufacturing industries since 2017. With a strong commitment to engineering excellence, we strive to deliver products with productivity and Quality assurance that match global standards in both performance and durability.

We manufacture a wide range of specialized pilger tooling including all types of Pilger Die & Mandrel. These components are essential in cold pilgering operations, and our products are crafted with precision to ensure reliable results and high operational efficiency in critical forming applications.

Every product at Shree Krishna Technomac is developed through a controlled process using high-grade materials and advanced machining techniques. Our in-house quality systems ensure dimensional accuracy, surface finish, and tool longevity. We continuously invest in technology and skilled manpower to meet and exceed customer expectations with consistency.

We are more than just a product provider - we are a dependable partner to manufacturers across India and abroad. By offering dependable service, prompt support, and tailored solutions, we have earned the trust of clients in various tube manufacturing industrial sectors. Whether the requirement is standard or customized, we ensure end-to-end satisfaction with clients.

Driving Innovation with Experience

Since our establishment in 2017, we have remained committed to innovation, cost-efficiency, and customer value. As the demands of the metal processing sector evolve, we continue to adapt and deliver cutting-edge solutions that empower our clients to achieve better productivity, reliability, and product quality.

Why Us?

We are more than just a product provider - we are a dependable partner to manufacturers across India and abroad. By offering dependable service, prompt support, and tailored solutions, we have earned the trust of clients in various tube manufacturing industrial sectors. Whether the requirement is standard or customized, we ensure end-to-end satisfaction with clients.

Driving Innovation with Experience

Since our establishment in 2017, we have remained committed to innovation, cost-efficiency, and customer value. As the demands of the metal processing sector evolve, we continue to adapt and deliver cutting-edge solutions that empower our clients to achieve better productivity, reliability, and product quality.

Why Us?

- Precision-Engineered Components: High dimensional accuracy and finish to enhance forming performance.

- Advanced Manufacturing Setup: Equipped with modern tools and technologies for reliable and repeatable quality.

- On-Time Delivery: Strong logistics and planning ensure timely dispatch of every order with prime quality.

- Consistent Quality Assurance: In-house testing and inspection to meet client and industry expectations.

- Trusted Across Industries: A proven track record of client satisfaction in both domestic and international markets.

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese